A Buyer's Guide to Rigid Heddle Looms

There's something beautifully deceptive about rigid heddle looms. They look almost primitive - a frame, a slotted piece that moves up and down, some string. Then you watch someone work one, the rhythm of it, the way finished cloth emerges from what seemed like chaos twenty minutes ago. These looms occupy fascinating territory: sophisticated enough to weave fabric that rivals commercial textiles, simple enough that you're actually weaving within an hour of setup rather than still consulting diagrams. The cloth that comes off these things holds together, wears well, becomes the kitchen towel that outlasts the store-bought ones, the scarf that gets compliments from people who don't even know it's handmade.

The market has essentially become a two-horse race between Boulder and New Zealand, between maple precision and beech modularity, between Schacht's "this is exactly what you need" philosophy and Ashford's "but what if you want to try something weird?" approach. Both companies have been at this long enough that their worst looms are better than most competitors' best efforts.

What nobody tells you - what the cheerful YouTube tutorials skip over - is that choosing a rigid heddle loom isn't really about the loom at all. It's about the kind of weaver you'll become. The person who weaves kitchen towels with mechanical precision, or the one who decides at 11 PM that fabric strips might make interesting weft material. The equipment shapes the practice as much as the practice shapes the output.

The Architecture of Simplicity

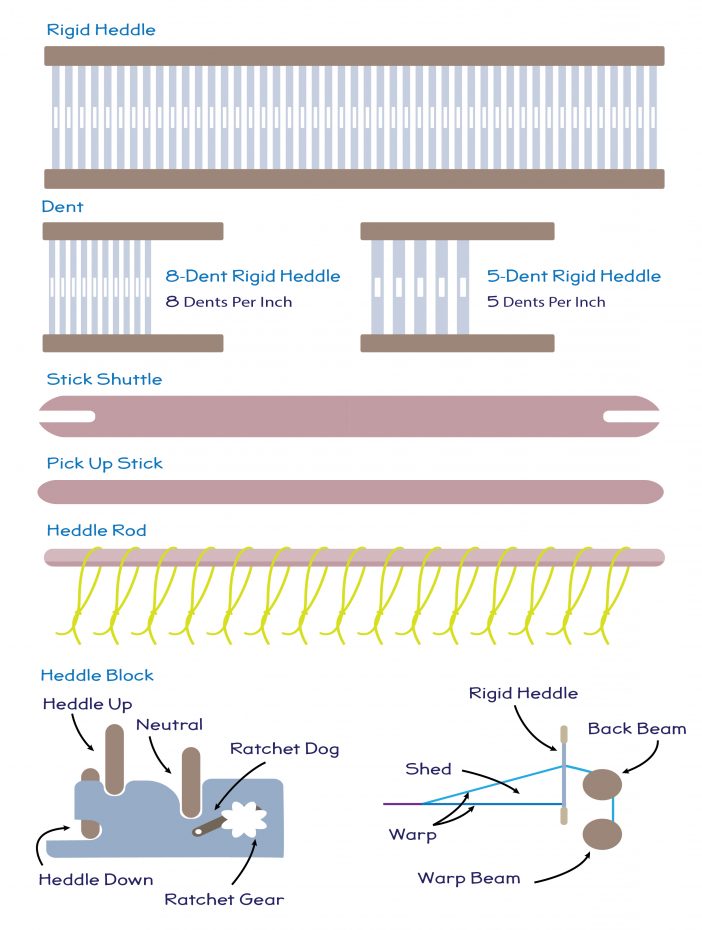

A rigid heddle loom reduces weaving to its essential mechanics: threads go up, threads go down, shuttle passes through. The heddle - that slotted plastic or wood piece that looks like a very specialized comb - controls everything. Pull it up, half the threads rise. Push it down, the other half rise. That's your entire pattern vocabulary right there.

The genius lies in what's been removed rather than what's been added. No castle - that towering framework of traditional looms. No treadles to coordinate with your feet while your hands work the shuttle. No complex tie-up patterns that require graph paper and patience. Just slots and holes, alternating threads, and the rhythm of weaving stripped to its core.

Yet this simplicity enables surprising complexity. Double heddles create pattern possibilities that approach four-shaft territory. Pick-up sticks add texture and design elements. Varied yarn weights and colors transform basic tabby weave into sophisticated cloth. The limitation becomes liberation - with fewer variables to manage, you can focus on the actual weaving. Like other detailed fiber crafts, weaving benefits from proper lighting to see threading and pattern errors.

Market Reality Check: What Actually Exists in 2025

| Model | Width Options | Included Heddle | Available Dent Sizes | Key Features | Current Price Range |

|---|---|---|---|---|---|

| Schacht Cricket | 10", 15" | 8 dent | 8, 10, 12, 15 | Front/back beams, maple construction | $195-$245 |

| Ashford SampleIt | 10", 16" | 7.5 dent | 2.5, 5, 7.5, 10, 12.5, 15 | Built-in second heddle slot, silver beech | $180-$230 |

| Schacht Flip | 15", 20", 25", 30" | 10 dent | 5, 8, 10, 12 | Foldable, top cross brace, pre-finished | $425-$595 |

| Ashford Knitter's | 12", 20", 28" | 7.5 dent | 2.5, 5, 7.5, 10, 12.5, 15 | Foldable, carrying case included | $385-$485 |

| Ashford Rigid Heddle | 24", 32", 48" | 7.5 dent | 2.5, 5, 7.5, 10, 12.5, 15 | Double heddle capability, large format | $345-$645 |

The price spread reflects more than size differences. Folding mechanisms add $150-200 to comparable fixed models. Wider looms command premiums not just for materials but for the engineering required to maintain rigidity across increased spans. That 48-inch Ashford costs nearly as much as entry-level multi-shaft looms, targeting weavers who specifically want rigid heddle simplicity at production scale.

Schacht Cricket: When Less Is Deliberately More

The Cricket embodies a very particular worldview: that most weavers work with standard yarns on standard projects and would prefer equipment that excels at those tasks rather than accommodating edge cases. It's weaving equipment designed by people who actually weave, regularly, and have opinions about ratchet pawl engagement angles.

- 8-dent rigid heddle included (covers worsted weight yarns)

- Front and back beams prevent fabric buildup on longer warps

- Maple construction requires finishing but allows customization

- Complete kit includes shuttles, clamps, warping peg

The front and back beam system reveals Schacht's priorities. As you weave, finished fabric travels up and over the front beam while maintaining consistent shed geometry. Most rigid heddle looms wind fabric directly onto a single beam, gradually reducing shed size as fabric accumulates. The Cricket maintains that shed opening whether you're weaving inches or yards.

The ABS plastic heddle teeth resist bending better than nylon alternatives - a durability detail that matters after hundreds of shed changes. The ratchet mechanism engages positively without requiring careful finger placement to prevent slippage. These aren't features that photograph well or sell looms, but they're the difference between equipment you use and equipment you endure.

What the Cricket deliberately omits: provision for multiple heddles (though workarounds exist), excessive width options (10 or 15 inches only), and the full range of heddle sizes. Schacht figures if you want to weave rugs, you'll buy a rug loom. If you want complex patterns, you'll graduate to a multi-shaft loom. The Cricket does its specific job exceptionally well rather than doing many jobs adequately.

Ashford SampleIt: The Experimenter's Platform

Where Schacht builds for the median weaver, Ashford accommodates the outliers. The SampleIt acknowledges that someone, somewhere, wants to weave with fishing line, or strips of plastic bags, or hand-spun yarn that varies from thread to rope within a single skein. It's equipment for people who view "that won't work" as a challenge rather than a warning.

- 7.5-dent heddle included (metric equivalent to 8-dent)

- Built-in slot accepts second heddle without modification

- Silver beech construction with natural oils for moisture resistance

- Ratchet system with audible positive engagement

The second heddle capability transforms possibilities without complicating basic operation. Two heddles enable color effects that single heddles can't achieve - warp stripes that appear and disappear, textures that emerge from thread interaction rather than yarn choice. The slot sits empty until needed, adding no complexity for single-heddle work.

That 2.5-dent heddle option - suitable for yarn thick as your finger - opens territories most rigid heddle looms can't explore. Rag rugs, art weaving with unconventional materials, the kind of experimental textiles that end up in galleries rather than on tables. The 15-dent option handles threads fine enough for dress fabric. This range acknowledges that weaving encompasses more than dishcloths and scarves.

The ratchet design eliminates the tension-dependent engagement that plagues cheaper looms. You hear each tooth engage, feel the positive lock, know exactly where you've advanced the warp. It's mechanical communication at its most direct - the loom telling you it's ready for the next pick.

The Folding Question: Engineering Versus Reality

Schacht Flip: Precision Portability

The Flip addresses the eternal craft room dilemma: limited space, unlimited ambition. It folds mid-project, letting you reclaim your dining table without destroying three hours of warping work. Available from 15 to 30 inches wide, it scales from personal projects to household textiles.

- 10-dent heddle included (medium-weight yarn standard)

- Top cross brace enables 15-18 foot warps without shed reduction

- Multiple heddle slots built into frame design

- Hand-rubbed Danish oil finish needs no additional treatment

The top cross brace replaces the Cricket's beam system while achieving the same goal - maintaining consistent shed geometry across long warps. This engineering enables blanket-length projects on equipment that folds into a closet. The mechanism locks positively in both folded and working positions, eliminating the wobble that makes some folding looms feel provisional.

Pre-finishing represents Schacht's acknowledgment that some weavers want to weave, not woodwork. The Danish oil treatment protects the maple while enhancing grain visibility. The surface feels furniture-smooth from first use, developing deeper luster with handling rather than requiring initial treatment.

The price premium over non-folding models - roughly $200 - buys genuine portability rather than theoretical portability. Workshop attendees report flying with Flip looms as checked baggage. The fold mechanism survives years of regular use without developing play or requiring adjustment.

Ashford Knitter's Loom: The Traveling Weaver's Companion

Ashford took a different approach: if it's going to fold, it might as well travel properly. The Knitter's Loom includes a padded carrying case with organized pockets for heddles, shuttles, and tools. It's weaving equipment designed for people who weave in multiple locations.

- 7.5-dent heddle with full range of options available

- Superior ratchet system with tension-free positive locking

- Padded case with accessory storage

- Built-in second heddle capability

The carrying case transforms this from furniture to luggage. Interior pockets hold shuttles securely, preventing the rattling that drives travel companions insane. External pockets accommodate heddles, threading hooks, and project notes. The padding actually protects - several weavers report checking these as airline baggage without damage.

The ratchet mechanism represents Ashford's best engineering. Unlike the SampleIt's already-good system, this one achieves mechanical perfection. Each tooth engages with an audible click regardless of warp tension. The pawl won't slip even with the warp completely slack - useful when troubleshooting threading errors or adjusting tension mid-project.

Available widths from 12 to 28 inches accommodate different project scales, though the 20-inch model hits the sweet spot for portability versus capability. The 28-inch version stretches the definition of "portable," but some weavers prioritize width over weight.

When Size Actually Matters: Production-Scale Rigid Heddle

Ashford's large-format rigid heddle looms - up to 48 inches wide - occupy peculiar territory. They cost nearly as much as entry-level multi-shaft looms while offering less pattern complexity. Yet they sell steadily to weavers who want rigid heddle simplicity at production scale.

- 7.5-dent heddle scales to full width

- Double heddle blocks enable complex structures

- Enhanced ratchet system handles increased tension

- Silver beech construction requires finishing

The appeal becomes clear in practice. Threading a 48-inch rigid heddle takes an hour. Threading a 48-inch multi-shaft loom takes a day. The rigid heddle maintains its quick-setup advantage even at scale. Production weavers making dozens of placemats or kitchen towels save days of setup time over a year.

The engineering challenges multiply with width. Maintaining consistent tension across 48 inches requires substantial frame rigidity. The enhanced ratchet system must hold against significantly more total force. The heddle itself becomes unwieldy - lifting 48 inches of warp threads requires deliberate technique rather than casual motion.

These looms suit specific situations: production weaving of simple fabrics, teaching environments where multiple students need equipment, weavers with mobility limitations who find multi-shaft loom treadling difficult. They're specialized tools rather than general-purpose equipment, priced accordingly.

The Heddle Ecosystem: Where Choices Multiply

The heddle collection pattern follows predictable stages. First loom arrives with standard heddle - 8-dent for Schacht, 7.5 for Ashford. Works fine for months. Then you inherit your grandmother's lace-weight yarn, or discover chunky wool at an irresistible price. Second heddle purchase follows. Within two years, most weavers own three to five heddles covering their preferred yarn range.

Schacht's focused selection - 8, 10, 12, and 15 dent - covers standard yarn weights efficiently. The gaps between sizes stay consistent enough that most projects clearly suit one size or another. The 8-dent handles worsted weight, 10-dent suits sport weight, 12-dent manages fingering weight, 15-dent tackles lace. Clean categories, clear choices.

Ashford's extended range - 2.5, 5, 7.5, 10, 12.5, 15 dent - acknowledges that yarn doesn't always fit neat categories. Hand-spun varies wildly. Art yarns defy classification. That 5-dent option bridges the gap between standard and chunky. The 12.5-dent splits the difference between fingering and lace. More options mean more possibilities but also more decisions.

Cross-compatibility doesn't exist. Ashford heddles won't fit Schacht looms without modification. The mounting systems, heddle heights, and frame dimensions differ enough that mixing brands requires genuine engineering rather than simple adaptation. Choose your ecosystem and commit.

Storage becomes its own consideration. Heddles need protection from warping (the wood kind, not the weaving kind). Most weavers hang them flat on walls or store them in padded cases. Some build dedicated heddle racks. The casual "leaning in the corner" approach leads to bent heddles and frustrated weaving sessions.

The Unmentioned Mathematics of Weaving Width

The 10-inch versus 15-inch decision seems simple until you calculate yardage reality. A 10-inch loom weaving 8-inch finished width (accounting for draw-in and finishing) needs 45 inches of fabric to make four placemats. A 15-inch loom weaving 13-inch finished width needs 28 inches for the same four placemats.

This calculation compounds across projects. Dish towel sets, table runners, scarves - wider looms consistently require less length for equivalent output. The time savings multiply when you consider warping effort. Setting up 45 inches versus 28 inches might save just minutes per project, but those minutes accumulate into hours over a year of weaving.

Yet narrower looms offer their own advantages. They require less physical space, both for storage and use. A 10-inch loom works comfortably on an airline tray table. The narrower shed requires less arm movement, reducing fatigue during long weaving sessions. The lighter weight matters for weavers with arthritis or limited hand strength.

The sweet spot for most weavers lands around 15-16 inches. Wide enough for practical household items, narrow enough for comfortable handling. Not coincidentally, this is where manufacturers concentrate their offerings. The 10-inch models suit specific needs - travel weaving, narrow items like belts and straps, weavers with limited space. The 20+ inch models serve production weavers and those making wider textiles.

Inside the Price-to-Performance Calculation

Budget rigid heddle looms from companies like Kromski, Harrisville, and various Chinese manufacturers typically cost 40-60% less than Schacht or Ashford equivalents. A functional 16-inch rigid heddle can be had for under $100. The question becomes whether saving $100-150 upfront justifies potential frustration.

The compromises cluster around precision and durability. Heddles made from inferior plastic bend under normal tension. Ratchet mechanisms develop play after months of use. Frame joints that seemed solid loosen gradually. None of these issues prevent weaving, but each adds friction to the process. When learning, you can't distinguish between your errors and equipment limitations.

The established manufacturers bring decades of iteration to their designs. Schacht's ratchet pawl angle wasn't randomly chosen - it represents optimization across thousands of use cases. Ashford's heddle slot spacing accommodates specific heddle combinations based on weaver feedback. These refinements seem minor individually but compound into significantly different user experiences.

For committed weavers, the math favors quality equipment. Spread across years of use, the price premium becomes negligible. For exploratory weavers testing interest, budget options provide functional entry points. The risk lies in equipment limitations discouraging continued practice - attributing difficulty to personal inability rather than tool inadequacy.

Used equipment offers another path. Rigid heddle looms hold value remarkably well. Quality looms from the 1980s still function perfectly. Estate sales, guild destashing, and online marketplaces regularly offer Schacht and Ashford looms at 60-70% of retail. Patience and willingness to drive for pickup can yield excellent equipment at budget prices.

The Learning Curve Nobody Mentions

Rigid heddle looms get marketed as "beginner-friendly," which is simultaneously true and misleading. Yes, you can produce fabric within hours of unpacking. No, that fabric won't initially resemble your intentions. The simplicity of operation masks complexity of technique.

Tension consistency takes months to develop. Too tight, and your fabric becomes bulletproof. Too loose, and threads tangle into chaos. The sweet spot varies with yarn weight, fiber content, humidity, and phase of the moon (seemingly). Experienced weavers develop intuitive tension sense. Beginners wrestle with every adjustment.

Beat consistency - how firmly you press each weft thread into place - determines fabric hand more than any other factor. Heavy beats create firm, stable fabric. Light beats produce drapey, flexible cloth. Inconsistent beats create fabric with personality disorders. The rhythm takes time to develop, and rigid heddle looms offer less mechanical assistance than multi-shaft looms.

Yarn choice influences success more than equipment choice. Mercerized cotton behaves predictably. Wool forgives tension variations. Linen fights you until it doesn't. Novelty yarns create interesting effects or complete disasters with little middle ground. Starting with cooperative yarns reduces variables while learning.

The Community Ecosystem

Rigid heddle weavers occupy interesting space in the broader weaving community. Multi-shaft weavers sometimes view them as training wheels enthusiasts. Historical recreation weavers consider them insufficiently authentic. Art weavers question their creative limitations. Yet rigid heddle weaving maintains vibrant, supportive communities both online and locally.

YouTube University offers thousands of hours of rigid heddle instruction. Jane Patrick (Schacht's creative director) maintains extensive video archives. Ashford's YouTube channel provides project-specific guidance. Independent creators like Kelly Casanova and Liz Gipson built entire educational ecosystems around rigid heddle weaving.

Local guilds increasingly embrace rigid heddle weavers. The portability enables workshop participation. The quick setup allows demonstration at public events. The approachability attracts new members who might find multi-shaft looms intimidating. Some guilds maintain rigid heddle looms specifically for introductory classes.

Online communities provide 24/7 troubleshooting support. Facebook groups like "Rigid Heddle Weaving" host tens of thousands of members sharing projects, solving problems, and enabling yarn acquisition disorders. Reddit's r/weaving includes dedicated rigid heddle threads. Ravelry maintains extensive rigid heddle forums and pattern databases. Once you've chosen your loom, understanding pattern notation becomes essential for accessing the thousands of published patterns these communities share.

Future-Proofing Your Choice

Rigid heddle looms rarely become obsolete. The mechanical simplicity that defines them also ensures longevity. Thirty-year-old Schacht looms weave identically to current models. Ashford looms from the 1970s still produce beautiful cloth. The technology peaked decades ago; current improvements focus on convenience rather than capability.

Replacement parts remain available for established brands. Heddles crack occasionally. Pawl springs wear out eventually. Shuttles disappear mysteriously. Both Schacht and Ashford maintain parts inventory for discontinued models. Third-party suppliers offer alternatives. The standardization of heddle sizes means options exist even if manufacturers disappear.

Resale values stay strong for quality equipment. Rigid heddle looms depreciate less than most craft equipment. Well-maintained looms sell for 70-80% of retail price. Even damaged looms find buyers willing to restore them. The combination of simplicity and durability creates enduring value.

The upgrade path stays open without abandoning rigid heddle weaving. Many weavers who advance to multi-shaft looms keep their rigid heddle for quick projects, travel, or teaching. The skills transfer directly - yarn management, tension control, beat consistency apply regardless of loom complexity. Starting with rigid heddle provides foundation without limiting future options.

The Pattern of Purchase Decisions

Schacht buyers tend toward precision and repeatability. Their project photos show consistent selvages, even beat patterns, standard yarn weights. The Cricket appears most frequently in studios where weavers produce multiples - sets of placemats, dozen-towel wedding gifts, craft fair inventory. The Flip shows up in workshop photos and travel documentation, owned by weavers who teach or attend multiple guilds.

Ashford equipment clusters around experimentation and adaptation. SampleIt looms appear surrounded by unusual materials - handspun with dramatic thick-thin variations, recycled sari silk, paper yarn experiments. The online forums show these weavers asking "what if" questions rather than "how to" questions. Knitter's Loom owners post from hotel rooms, vacation rentals, and retreat centers with remarkable frequency.

The width decision correlates strongly with available space and project ambition. Urban weavers gravitate toward 10-12 inch models that fit apartment reality. Suburban and rural weavers more commonly own 15-20 inch looms. The 24+ inch models appear almost exclusively in dedicated studio spaces or teaching environments.

Budget loom purchases follow two distinct patterns: temporary exploration or permanent frustration. The successful cases involve weavers who upgrade within six months, treating the budget loom as extended equipment rental. The frustrated cases show years of fighting equipment limitations, often visible in project photos as uneven selvages and tension problems.

The multiple heddle accumulation happens with startling consistency. Purchase records from major suppliers show second heddle purchases typically occur 3-6 months after initial loom acquisition. Third and fourth heddles follow within the first two years. Most active weavers plateau at 4-5 heddles covering their preferred yarn range.

The truth about rigid heddle looms - the thing the cheerful blog posts and helpful videos don't quite capture - is that they're genuinely transformative. Not in some mystical "connecting with ancient traditions" way, but in the practical sense of producing useful textiles with your own hands. That dishcloth in your kitchen, woven while watching Netflix, represents capability most humans lost generations ago. The equipment just makes it possible. What you do with that possibility becomes the interesting part.