Hardness Testing in Practice: Beyond the Mohs Scale

Every lapidary book includes the same chart. The Mohs hardness scale, running from talc at 1 to diamond at 10, with neat little boxes explaining that each mineral scratches everything below it. Quartz sits at 7. Corundum at 9. The chart suggests a tidy progression where hardness increases in predictable increments.

The Mohs hardness scale showing relative scratch resistance from talc (1) to diamond (10). Image: Kilawyn Punx, CC BY-SA 4.0, via Wikimedia Commons

The Mohs hardness scale showing relative scratch resistance from talc (1) to diamond (10). Image: Kilawyn Punx, CC BY-SA 4.0, via Wikimedia Commons

Then you're standing in your workshop holding a stone you found in a riverbed, trying to figure out if it'll survive your grinding wheels or turn into expensive dust. The chart doesn't tell you what a hardness test actually looks like, or why stones that test identically can behave completely differently when you start cutting them.

The Mohs scale measures scratch resistance. That's it. Not toughness. Not brittleness. Not how the material responds to sustained abrasion from a 220-grit diamond wheel spinning at 1,725 RPM. Just whether mineral A can scratch mineral B.

This matters more than the textbooks suggest.

The Tools That Actually Work

A proper mineralogy lab has calibrated testing equipment and reference specimens of known hardness. Most home lapidary workshops have a drawer full of random tools accumulated over years, some of which happen to be useful for hardness testing.

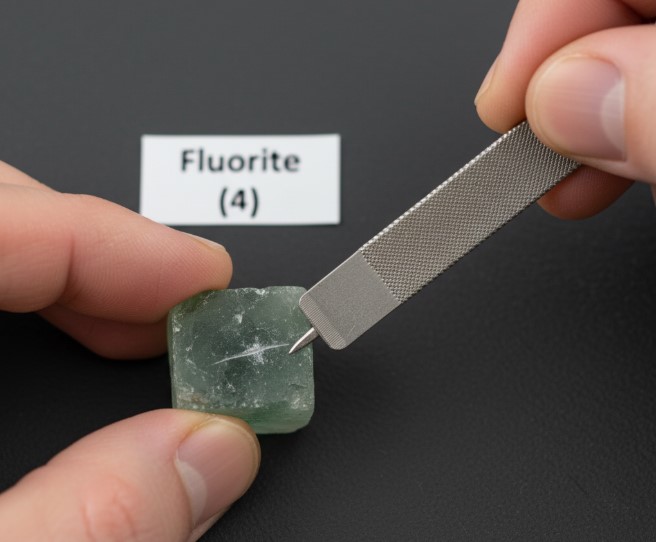

Scratch testing with a steel file - the most practical field test for determining if a stone is harder or softer than 6.5 on the Mohs scale

Scratch testing with a steel file - the most practical field test for determining if a stone is harder or softer than 6.5 on the Mohs scale

A steel file tests around 6.5 on the Mohs scale. Run it across a stone's surface with moderate pressure. If the file skates across without catching and leaves no visible mark, the stone is harder than the file. Probably quartz or something in that family. If the file bites in and produces powder, the stone is softer than steel. Could be calcite, fluorite, or dozens of other minerals that won't hold up well to standard lapidary equipment.

The test takes five seconds and eliminates huge categories of possibilities.

A pocket knife blade sits around 5 to 5.5 on Mohs. It scratches calcite (hardness 3) and fluorite (hardness 4) but not apatite (hardness 5) or anything harder. This middle range matters because some attractive stones fall into this zone where they're soft enough to work easily but hard enough to hold a decent polish with the right approach.

Glass plates test around 5.5 to 6. They scratch anything softer but get scratched by anything harder. A piece of window glass from the hardware store serves the same purpose as the glass plates in a testing kit. Drag the stone across the glass with pressure. If it leaves a scratch, it's harder than glass. If it doesn't, run the glass across the stone. One of them scratches the other.

Ceramic tiles, the unglazed kind from flooring suppliers, sit around 7 on the Mohs scale. Similar to quartz. A stone that scratches ceramic tile is hard enough for standard lapidary work. A stone that doesn't scratch ceramic might still be plenty hard, since the difference between 6.5 and 7 is small.

Fingernails test at 2 to 2.5. Human fingernails are softer than most materials worth cutting, but the fingernail test identifies the truly soft minerals quickly. If a fingernail leaves a visible scratch, you're holding talc, gypsum, or something equally soft. These materials rarely show up in lapidary work unless someone specifically wants to work with them for educational purposes.

Each tool provides a data point. Three or four data points usually narrow identification enough to make decisions about how to proceed.

Relative Hardness vs Absolute Hardness

Here's where the Mohs scale misleads through simplicity. The numbers suggest equal spacing. Going from 3 to 4 looks like the same jump as going from 7 to 8 or 9 to 10. The actual hardness differences aren't linear at all.

Corundum (hardness 9) is approximately twice as hard as topaz (hardness 8) in terms of absolute scratch resistance. Diamond (hardness 10) is roughly four times harder than corundum. The gaps between numbers grow dramatically at the upper end of the scale.

This matters when you're working with stones near the boundaries between categories. A stone at 6.5 and a stone at 7 test almost identically with simple scratch tests, but one might be noticeably easier to grind than the other. The Mohs scale doesn't capture those subtle differences.

Jade presents a famous example of why the scale can mislead. Nephrite jade tests around 6 to 6.5 on Mohs. Jadeite jade hits 6.5 to 7. Both are softer than quartz (hardness 7), yet experienced lapidaries know jade as one of the tougher materials to work with. It grinds slowly. It resists fracturing. It feels different on the wheel compared to jasper or agate, despite testing at similar hardness levels.

Jade (left) and quartz (right) test at similar hardness but behave completely differently during cutting - jade's interlocking crystal structure makes it tougher despite lower scratch resistance

Jade (left) and quartz (right) test at similar hardness but behave completely differently during cutting - jade's interlocking crystal structure makes it tougher despite lower scratch resistance

The confusion comes from conflating hardness with toughness. Hardness measures scratch resistance. Toughness measures resistance to breaking or chipping. Jade has high toughness due to its interlocking crystal structure, even though its hardness is moderate. Diamond has extreme hardness but relatively low toughness compared to jade, which is why diamonds can chip if struck wrong despite being the hardest natural material.

Obsidian demonstrates the opposite relationship. It tests around 5 to 5.5 on Mohs, softer than quartz, but it fractures easily because volcanic glass has no crystal structure to provide toughness. Obsidian cuts cleanly but chips at the edges if handled roughly during shaping.

Why "Hardness 7" Doesn't Mean Much

Quartz, jasper, agate, chalcedony, amethyst, citrine, and dozens of other varieties all test at 7 on the Mohs scale. They're all silicon dioxide with minor variations in structure and impurities. The hardness testing is identical. The cutting behavior varies.

Chalcedony grinds differently than crystalline quartz despite being the same mineral at different crystal sizes. The microcrystalline structure of chalcedony means it removes more smoothly from grinding wheels, while larger quartz crystals can fracture unpredictably during aggressive material removal.

Jasper, which is chalcedony with significant impurities, behaves differently still. The iron oxide and other minerals mixed into the silica matrix affect how it responds to grinding and polishing. Some jasper varieties are easy to work. Others load up grinding wheels or resist taking a high polish despite testing at the same hardness.

This creates problems when lapidaries try to predict cutting behavior based solely on hardness numbers. Two stones at hardness 7 might require completely different grit progressions to achieve similar polish quality. The Mohs number provides a starting point but not a complete picture.

Stone identification requires looking at multiple characteristics together rather than relying on hardness alone.

The Destructive Nature of Testing

Every scratch test leaves a permanent mark. Run a steel file across a stone and you've damaged that spot. The scratch might be minor, barely visible, but it's there. Polish that stone later and the scratch may show up as a line across an otherwise smooth surface.

This forces a choice. Test the stone and know what you're working with, or skip testing and risk wasting time on material that won't survive the cutting process.

Most experienced cutters test in spots they plan to remove anyway. The edges that'll be trimmed during initial shaping. The rough areas that won't make it into the final piece. A corner that's already fractured or weathered.

On rough material straight from the field, this isn't difficult. Most found stones have enough excess material that losing a small test area doesn't matter. On expensive purchased rough, particularly small pieces where every gram counts, the decision gets harder.

Some stones show weathering that affects surface hardness differently than interior hardness. River rocks develop rinds where repeated wetting and drying has slightly altered the mineral structure. Test the weathered exterior and you might get a different reading than testing a fresh break into the interior.

This shows up particularly with agates and jaspers. The outer surface might test slightly softer than the interior due to microscopic fracturing from temperature cycles or mineral leaching. Break the stone open and test the fresh surface for more accurate results.

The scratches from hardness testing don't affect structural integrity. They're surface marks. But they affect aesthetics on finished pieces. A scratch from a knife blade shows as a visible line through polish on translucent materials like agate or chalcedony. On opaque materials like most jasper, scratches are less visible but still detectable under close examination.

Cabinet specimens, stones kept for display rather than cutting, shouldn't be tested destructively if you want to maintain their original surface. The choice becomes identification confidence versus preservation of the natural surface.

What Hardness Predicts (and What It Doesn't)

Hardness testing tells you about abrasion resistance. A harder stone resists wear from grinding more than a softer stone. This predicts how quickly material removes during shaping and roughly how long the stone will hold a polish under normal handling.

It doesn't predict brittleness. Glass is harder than most people expect, around 5.5 to 6 on Mohs, but drops easily fracture it. Jade is relatively soft but incredibly tough. Diamond is the hardest natural material but can cleave along crystal planes if struck at the right angle.

It doesn't predict how the stone behaves under sustained cutting. A lapidary saw blade doesn't scratch material off like a hardness test does. It grinds through using diamond particles embedded in metal or resin. The cutting action involves compression, fracture propagation, and heat generation. Hardness matters but so does crystal structure, internal stress patterns, and how the material conducts heat away from the cutting zone.

Two stones at the same hardness can respond completely differently to grinding wheels. One might load up the wheel with residue while the other grinds cleanly. One might generate more heat during cutting. One might fracture more readily at sharp angles.

Hardness does correlate reasonably well with polish quality in the quartz family. Harder materials generally take higher polish if all other factors are equal. But "all other factors" rarely are equal. The presence of internal fractures, the size and arrangement of crystal structures, and the specific mineral impurities all affect final polish independent of hardness.

Soft stones can achieve excellent polish under the right conditions. Calcite (hardness 3) polishes to high gloss when worked with appropriate compounds and careful technique. The polish scratches more easily than quartz polish, but the immediate visual result can be similar. The difference shows up in durability over time rather than initial appearance.

Some lapidaries avoid soft materials entirely because the workshop setup gets complicated. Soft stones gum up wheels designed for harder materials. They require different grinding compounds. They need gentler pressure during polishing. Mixing soft and hard stone work in the same session means more equipment cleaning and wheel changes.

Others specialize in soft materials precisely because the cutting behavior is different. Lower hardness means faster material removal with less aggressive grinding. Less risk of thermal shock from friction heat. Different aesthetic possibilities from materials that don't appear in typical lapidary collections.

Field Testing Limitations

A pocket knife and a steel file cover most practical hardness testing situations. They establish whether a stone is harder or softer than steel, which is usually enough information to decide whether to proceed with cutting.

They don't distinguish between materials in the same hardness range. Quartz at 7 and beryl at 7.5 to 8 test nearly identically with simple tools. Both are harder than steel, both scratch glass and ceramic. The half-point difference matters if you're trying to identify a specific mineral species, but for practical lapidary work they behave similarly enough that the distinction rarely affects cutting decisions.

Complex material compositions resist field testing entirely. Rocks made of multiple minerals, like granite, show different hardness in different areas depending on which mineral you're testing. The quartz portions test at 7. The feldspar tests at 6. The mica tests around 2.5 to 3. Run a file across granite and the result depends on which mineral you happened to contact.

Some minerals have directional hardness variation. Kyanite famously tests at hardness 5 parallel to crystal length and hardness 7 perpendicular to crystal length. A single stone gives different hardness readings depending on testing direction. This is rare but creates confusion when it occurs.

Treated stones present identification problems. Stabilized turquoise (turquoise impregnated with resin) tests harder than natural turquoise because you're partially testing the resin rather than pure mineral. Dyed materials, coated materials, or composite materials all give hardness readings that don't match the base mineral.

Proper identification sometimes requires laboratory equipment. Specific gravity testing (measuring density by water displacement) helps distinguish between materials of similar hardness but different density. Refractive index testing (measuring how light bends through the material) identifies transparent to translucent stones more definitively than hardness alone. Spectroscopy reveals exact chemical composition.

Most home workshops don't have this equipment. The investment runs into thousands of dollars for reliable testing apparatus. For hobbyist lapidaries working with found stones or inexpensive rough, the cost exceeds any practical benefit. For commercial cutters working with valuable material where misidentification could cost hundreds of dollars per stone, the equipment makes financial sense.

Gemological laboratories offer testing services for a fee. Send in a sample, receive back a detailed report identifying the material and noting any treatments. This works for small valuable specimens where accurate identification matters for pricing or legal disclosure requirements. It doesn't work for the bucket of random stones picked up on a weekend rock hunting trip.

Testing as Pattern Recognition

Experienced lapidaries develop an intuitive sense for hardness that goes beyond formal testing. The sound a stone makes when tapped. The way it feels in the hand. The visual characteristics that correlate with specific hardness ranges.

This isn't magic. It's pattern recognition built over thousands of stones handled. Someone who has cut hundreds of pieces of jasper recognizes jasper by sight, texture, and heft without needing to scratch test every piece. The accumulated experience creates mental shortcuts.

New cutters don't have these shortcuts yet. Testing every stone makes sense early in the learning process. The scratch test results build the pattern recognition database. After testing fifty stones that all behave similarly, the characteristics that define that hardness range become familiar.

The Mohs scale provides shared vocabulary for communicating hardness between lapidaries. Saying "it's around 7" conveys useful information even though the scale's limitations are well understood. Everyone knows 7 means harder than steel, softer than corundum, somewhere in the quartz family or similar materials.

Online lapidary communities discuss hardness frequently, usually in the context of identifying unknown material or troubleshooting cutting problems. Posts include descriptions like "tests harder than glass, scratches ceramic tile easily" which locates the material around 7 on Mohs without requiring laboratory confirmation.

The practical application of hardness testing is less about precise numbers and more about sorting materials into categories. Harder than steel or softer than steel. Hard enough for standard equipment or soft enough to need specialized approach. Tough enough to survive aggressive grinding or delicate enough to require careful handling.

Those distinctions matter more in actual workshop practice than knowing whether something is exactly 6.5 or 7 on the Mohs scale.